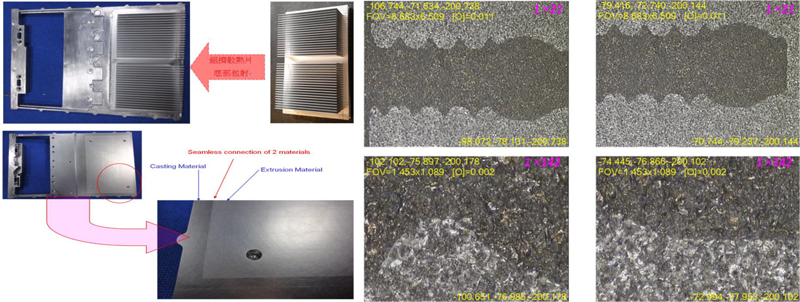

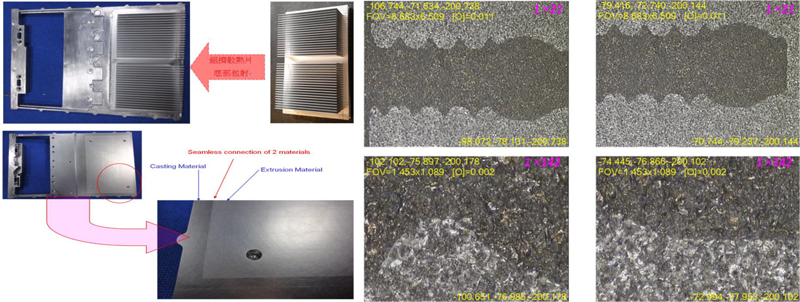

The traditional die-casting heat sink has many impurities, and the thermal conductivity is only 60%~75% of the aluminum alloy. In view of the high production efficiency and the advantages of various complicated structures at the same time, in order to compensate for the defects of thermal conductivity during thermal design, Often the amount is too heavy, the body is too large, and the advantages of die casting are not fully exerted.

The new patented technology uses aluminum alloy as the heat-dissipating body, the die-casting material is used as the structural support, and the aluminum alloy is used as the insert in the mold for one-time extrusion molding; the high-power and high heat flux density products can be used together with the superconducting uniform temperature plate. In the product, the problem of poor thermal conductivity of die-casting parts is solved by using the superconducting performance of the uniform temperature plate.